Company presentation

We are a medium-sized company with the core competence for CNC turning, milling and

Interlocking. Since our company was founded in 1996, our team has specialized in the production of gears, spare parts as well as precision turned and milled parts for machine, tool and fixture construction.

Business area - gears

Precision engineering module 0.15 - 1.0

- Spur gears - hub gears - helical gears - step gears

- Toothing module 1.0 - 10.0

- Straight and helical spur gears from module 1.0 - 10

- DP teeth from 5 - 18

- CP - toothing (after consultation) only 1/8 CP currently

- Sprockets up to 1 ″ pitch (25.4 mm), 1 1/4 pitch (31.75 mm)

- Splined shaft profile from 1.0 - 5.0 and all DP profiles

- Inside and outside diameter butt up to mod. 8

- Splined shaft: Mod. 1,0 - Mod. 5 - DP: 12/24 16/32 7/8/9/11

- Gear racks up to mod. 4

- Splines from 4 - 10

- Screws up to mod. 12

- Worm gears according to existing tools (after consultation)

- Keyways and keyways - slots up to 25 mm wide

- Grinding inside diameter up to workpiece Ø 250 mm

- Grinding outside diameter up to workpiece length 250 mm

Machine breakdown emergency service

- Gear repairs - spare parts production - repairs

Business area - CNC turning

As a service provider for contract work, we process precision turned parts up to 42 mm in diameter for clients from industry and the craft.

As a result, all machinable materials can be used and are manufactured according to the desired shape according to drawings or samples. Due to the planned structure, primarily small and medium series for rod and insert parts form the main part of the business activity.

The offer is supplemented by sample part production.

- Manufacturing of

- Short turned parts for a diameter of 2.0-42 mm

- Inserts up to a diameter of 50 mm with a tolerance> = IT 6

- End machining possible (total length up to 500 mm)

- Medium, small and pilot series / sample parts

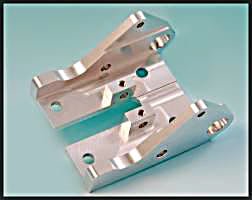

Business area - CNC milling

Milling area:

- up to 1200mm X-way, 730x650mm YZ-way - all-round processing ø up to 600 height 400

- Processing machines with 4 + 5 axes - CAD CAM system

Travels: X 560 / Y 400 / Z 510 mm

Travels: X 1200 / Y 730 / Z 650 mm

Material and material processing:

- Steel (construction, insert, tempering, nitriding and tool steels)

- Stainless steel (VA)

- Non-ferrous metals

- Non-ferrous metals

- Plastics / carbon

- titanium

- Special steels or provided blanks also cast parts

Ulrich Sehling - spare parts service

Heideweg 14 - D 31241 Ilsede

Tel .: 49 (0) 5171/590392 • Fax: 49 (0) 5171/5459039 • email: sehling@t-online.de

Partner: